Composite and aerospace cutting tools

Machine smarter to drive your cost-out and profit-up

Explore by category

Drill better holes, with FIBRODRILL™

Drilling composites? You need a drill that's been engineered to suit

There’s such a diversity of carbon fibre composites in use today that one drill doesn’t fit all.

We’ve united cutting-edge geometries with the latest wear-resistant materials, including CVD diamond coatings and PCD tips for optimal hole quality. Choose your next drill from the FIBRODRILL™ range, and boost your productivity.

All the angles, with FIBROSINK™

Got that sinking feeling? No worries

When you’re countersinking composite materials, standard countersinks just won’t do.

We’ve combined indexable inserts and pilots to create unparalleled flexibility so you can countersink and fillet radius composites at the angle you require. Order customised FIBROSINK™ products, and safeguard your productivity by increasing uptime and improving your operating costs.

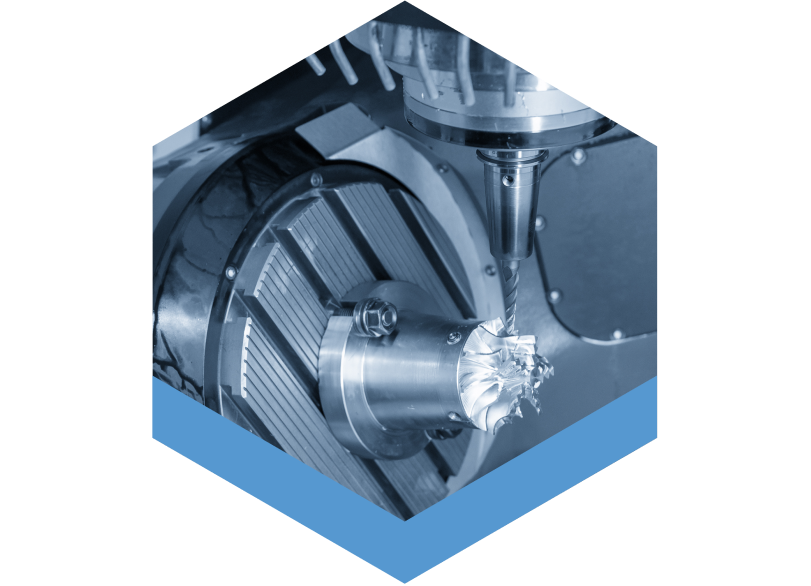

Edge ahead, with FIBROMILL™

Want the competitive edge? Composite milling made easy

Carbon composite materials are highly abrasive, which can make them tricky to machine effectively.

Consider FIBROMILL™ routers for easier milling of composites, and boost your productivity from the first cut.

Core appeal, with FIBROCORE™

Machining honeycomb core? Cut through it with ease

When machining honeycomb core materials, or when cutting composite or aluminum sandwich panels, you really need the finish to be clean. For rapid surfacing of large structures, or precision machining of slots, pockets and recesses.

Harness the matchless performance of FIBROCORE™, and see how much further you can go.

Make waves, with FIBROSURF™

Want a precise finish? Surface machining tools for composites

You want unrivalled machining performance from your composite surfacing tools.

We’ve united balanced, lightweight construction with advanced wear-resistant geometries for our high-speed composite surfacing tools. Try FIBROSURF™, and experience an enviable fusion of dynamic design and refined engineering.

Sonic boom, with FIBROSONIC™

Need a clean cut? Use ultrasonic knives.

When cutting composite fabrics, prepreg or honeycomb core materials, you need a clean cut.

Our FIBROSONIC™ ultrasonic knives are the trusted alternative to major brands. Whether you’re a global OEM or tier contractor company, get in touch to check them out.

How a Tier 1 Aerospace Team Cut Future Drilling Costs by 24%

After deploying Cajero’s indexable one-shot drill countersink system, the manufacturing team achieved the following…